close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

You need a NOx Sensor to comply with strict emissions regulations now. In the last ten years, many regions, including the European Union and China, have tightened their NOx limits. These new rules help reduce pollution from factories and vehicles. Advanced sensor technology, such as heat-resistant and self-checking features, provides you with reliable data. Smart monitoring allows you to effectively track and manage NOx levels, ensuring optimal performance in your operations. Kreation is at the forefront of this innovation, delivering solutions that meet the highest standards in emissions control.

NOx sensors are very important for checking nitrogen oxides in exhaust gases. They help industries follow strict emissions rules. Real-time monitoring of NOx levels lets workers act fast if emissions get too high. This stops fines and helps follow environmental laws. Regular maintenance and calibration of NOx sensors are needed for correct readings. This keeps them working well and helps avoid expensive repairs and legal trouble. Advanced NOx sensor technology makes work better by giving real-time data. This lets workers make quick changes to lower emissions. Using NOx sensors helps meet rules and also protects the environment. It can save money for businesses too.

A NOx sensor measures nitrogen oxides in exhaust gases. These gases come from engines and factories. NOx sensors help you watch NOx emissions and keep them safe. You find these sensors in cars, factories, and power plants. They are important for following emissions rules.

NOx sensors started in the 1990s. You see them in many cars and trucks. They are used with systems that absorb nitrogen oxides. Today, you depend on them for quick feedback. This feedback helps you change engine settings and control NOx. You use NOx sensors to help the environment and make air cleaner.

Tip: NOx sensors are needed to check NOx emissions and make sure your equipment follows the law.

You get help from special technology inside a NOx sensor. The sensor uses electrochemical cells to find NOx. Here is what happens:

The first cell removes oxygen. This stops other things from messing up the NOx reading.

The second cell splits NOx into nitrogen and oxygen with a catalyst.

The sensor checks the oxygen made. The electric current shows how much NOx is there.

You can look at the table to see the main parts and what they do:

Component/Principle | Description |

|---|---|

Sensor Structure and Startup Process | The sensor heats itself to 100℃, then to 800℃ for good detection. |

Detection Mechanism | Electrochemical reactions make signals that show NOx amount. |

Signal Processing | The sensor sends data to your engine control unit (ECU) with a CAN network. |

System Application | You check NOx levels before and after emission control to get best results. |

Self-Diagnosis | The sensor checks itself and tells the ECU if there is a problem. |

Hardware Features | The sensor is strong and uses special pins to show what it is. |

You get good results because the sensor works at high heat and uses solid electrolytes. The control module reads signals and talks to your ECU. You get fast data about NOx levels. The sensor also checks itself for problems, so you know when to fix it.

The sensor gives a signal that shows total NOx over time.

You see the NOx amount right now from the signal changes.

The sensor reacts in a straight line, so you get correct readings even when NOx is low.

You use NOx sensors to watch NOx emissions and keep your systems working well. This technology helps you follow tough emissions rules and keep the air clean.

You need to watch NOx closely to follow the rules. Many industries must meet strict limits for NOx emissions. The EPA’s Good Neighbor Plan sets a NOx budget for power plants and other businesses. These rules help cut pollution and keep the air clean.

Power plants in 23 states must drop NOx emissions from 208,119 tons in 2023 to 105,201 tons by 2029.

New rules will affect cement, iron and steel, glass, and chemical plants in 2026.

Some places might get more time if they meet special rules.

Real-time NOx monitoring gives you quick updates on NOx in exhaust. You can see when emissions go up or down right away. This helps you act fast if NOx gets too high and avoid fines. You use advanced NOx sensor technology to measure NOx in tough places. These sensors handle high heat and do not rust easily. They have smart tools like self-checks and ways to block false readings, so you get good data.

Note: Real-time monitoring helps you spot high NOx before it causes trouble. You can change your control systems or SCR units to lower NOx and stay within the rules.

You can use different technologies for real-time NOx monitoring:

Technology Type | Description |

|---|---|

Advanced Sensor Designs | Nanostructured electrodes and NOx trap materials boost sensitivity and selectivity. |

Miniaturization | Microelectronics make sensors compact and portable. |

Digital Control | Advanced signal processing improves accuracy and stability. |

Novel Materials | Al3+ ion conductors allow sensors to work at high exhaust temperatures. |

Optical Techniques | Photoacoustic and semiconductor methods detect NOx selectively. |

Laser-based and electrochemical sensors help you find small amounts of NOx and last longer. You can link these sensors to Industry 4.0 systems for remote checks and fixing problems before they happen. Cloud platforms let you see your data and plan how to control emissions.

New NOx exhaust gas analyzers can find NOx faster and more accurately. You get better NOx numbers, which is important for following the rules in real time.

You must report air pollution every year to the government. You pay fees based on how much you pollute. If you do not follow the rules, you could get big fines, lose your good name, pay more money, or face lawsuits. You might need to buy cleaner equipment or improve how you handle waste.

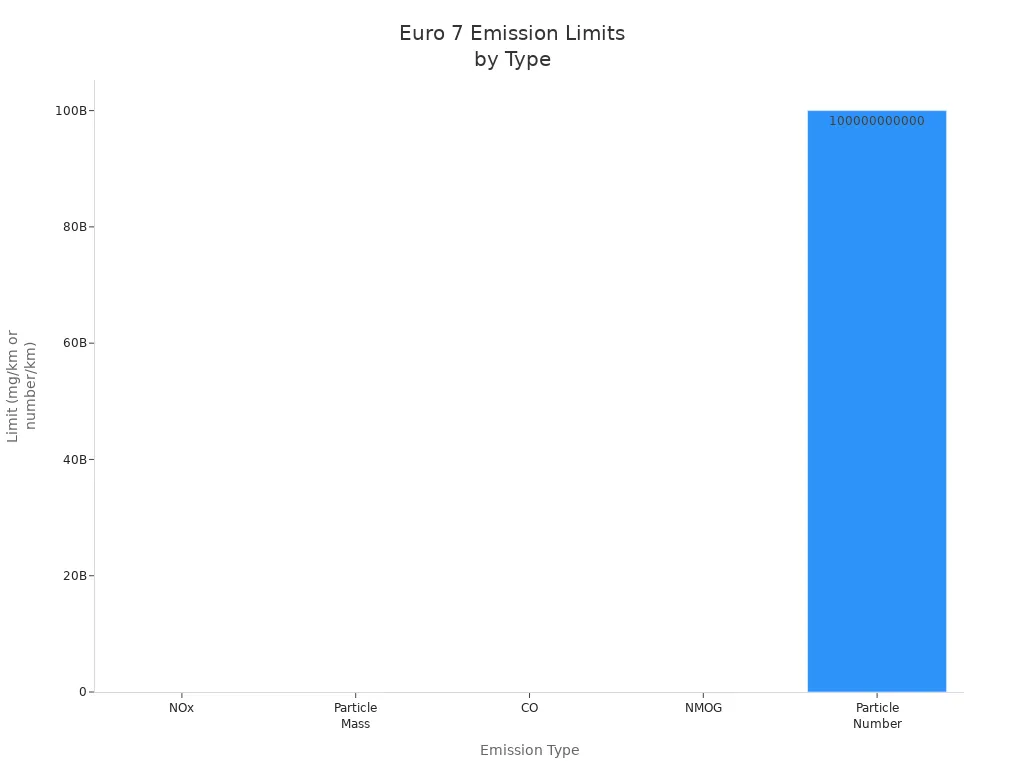

New rules like Euro 7 will make NOx limits even lower. You must get ready by using new NOx sensor technology. Euro 7 drops the NOx limit for vehicles from 80 mg/km to 60 mg/km. You need sensors that are more sensitive and accurate to meet these rules.

Tougher limits mean you need better after-treatment systems like EGR and SCR. You use NOx exhaust gas analyzers and NOx gas analyzers to check NOx in exhaust. These tools help you keep up with the rules and stay in compliance.

Alert: If you ignore high NOx, you could get big fines and legal trouble. You might also have trouble meeting the rules on time.

Good NOx sensors have heat resistance, self-checks, better strength, faster response, smaller size, and better protection from damage. These features help you get correct NOx readings and keep your exhaust systems working well.

You help lower NOx and protect the environment. Good NOx monitoring and reporting help you follow the rules, avoid fines, and make your work better.

A NOx sensor helps your facility follow emissions rules. It checks NOx levels in exhaust so you do not go over the limit. This keeps you from breaking strict laws. When you use advanced NOx exhaust gas analyzers, you get many benefits. You can:

Watch NOx in exhaust and act fast if it changes.

Stop problems by finding high NOx early.

Save money by avoiding fines for breaking rules.

Cut downtime by planning repairs on time.

Using a NOx gas analyzer often helps you meet rules. It also saves you money on repairs and legal trouble.

Your work gets better with advanced NOx exhaust gas analyzers and control systems. These sensors give you real-time data. You can change fuel and air in your exhaust system right away. This keeps NOx low and makes your system work better. IoT and predictive analytics help you find problems before they get worse. You can plan repairs and stop sudden shutdowns.

If you lower extra air in burning by 2%, you use up to 4% less fuel. You also cut NOx by up to 40%. These tools help you get more from your SCR and other exhaust controls.

You help the environment by using advanced monitoring and control. NOx sensors let you watch NOx in exhaust and take steps to lower it. This helps your company reach green goals and report on the environment. You also keep the air cleaner and protect people’s health by keeping NOx low.

Aspect | Description |

|---|---|

Reduction in Emissions | You see less NOx and N2O in exhaust with advanced sensors. |

Economic Benefits | You save money and make more by using exhaust controls and fertilizer better. |

Milestones and Indicators | You see progress with more sensors, field tests, and learning about cutting NOx. |

By using NOx exhaust gas analyzers, you show you care about clean air and better ways for the future.

You should look for signs your NOx sensor is not working right. If the check engine light comes on, check your exhaust system soon. You might see your engine misfire or notice black soot building up. Sometimes, your engine may speed up or slow down in a strange way. You could use more fuel or DEF than normal. Your vehicle might lose power or only drive slowly. These problems can mean your NOx emissions are too high and readings are not correct.

Check engine light

Engine misfire

Soot build-up

Strange speeding up or slowing down

Using more DEF

Using more fuel

Rough engine idle

Less power

Limp mode

If the NOx sensor stops working, your SCR system cannot control NOx in the exhaust. You could break emissions rules and laws. Wrong readings might make your car or machine fail checks. You could get fined or have to stop using your equipment. Sensor problems can also make SNCR and flue gas recirculation work worse. You need your NOx exhaust gas analyzers to work to stop pollution and keep things safe.

Alert: If you ignore these signs, you could cause more pollution and lose control of NOx emissions.

You need to keep your NOx sensor working right by checking it often. Most big systems need calibration every six months. Continuous Emission Control systems need checks every day and audits every three months. You do zero and span checks each day with special gas. These steps help you get the right NOx readings from exhaust.

Calibration Task | Frequency | Purpose |

|---|---|---|

Zero and Span Check | Daily | Make sure sensor is correct |

Full Calibration | Every 6 months | Keep sensor working well |

Quarterly Audit | Every 3 months | Follow the rules |

Advanced NOx exhaust gas analyzers from E-Quality help you take care of your sensors. These sensors can check themselves and tell you when they need calibration. You get a warning before the sensor starts to drift. The sensor can adjust for changes in exhaust and time delays. It uses the fuel mass signal from the ECU to match NOx readings with exhaust flow. This keeps your system ready for tests and makes sure it is correct.

You need to keep your NOx gas analyzer and NOx exhaust gas analyzers in good condition. Regular care helps you follow the rules and stop pollution. You protect your equipment and keep your readings right. You also help your SNCR and flue gas recirculation systems work better.

Tip: Use sensors that check themselves and give alerts. You save time and keep your NOx emissions under control.

You use NOx monitors to check your exhaust systems. This helps you follow emissions rules. Real-time monitoring shows concentration in exhaust right away. You can lower pollution and control your system better. Many industries use these sensors to keep concentration low. They also save money and help the environment. When rules get stricter, you need sensors that work in tough exhaust. These sensors must give steady and correct results. Pick solutions that last long and can change with new rules.

Factor | Why It Matters |

|---|---|

Accuracy | Shows concentration in exhaust |

Durability | Works in rough exhaust conditions |

Adaptability | Gets you ready for new rules |

Pick advanced NOx monitors with self-checks and heat resistance. This helps you follow rules and work better for a long time.